Core Section

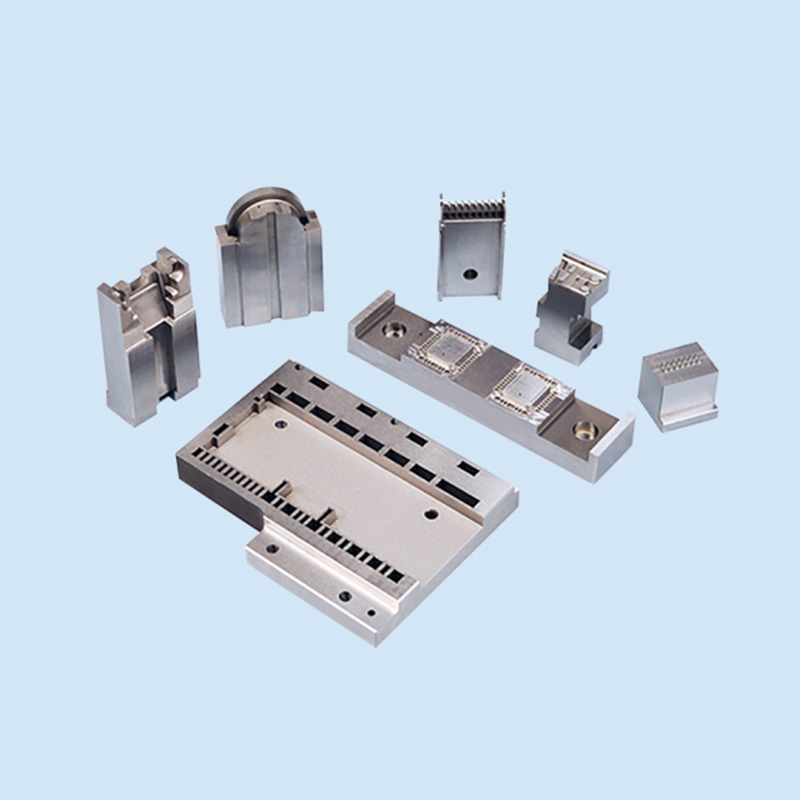

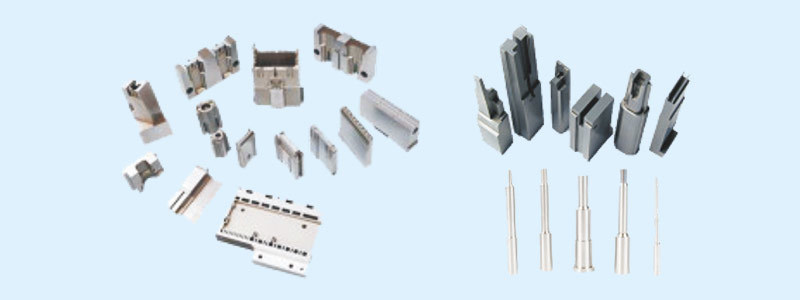

Development of precision injection molding, plastic pressing and stamping dies. In defense, new energy, automotive, communications, photovoltaic, high-speed, civil and industrial connectors and other fields have deep mold design, manufacturing experience.

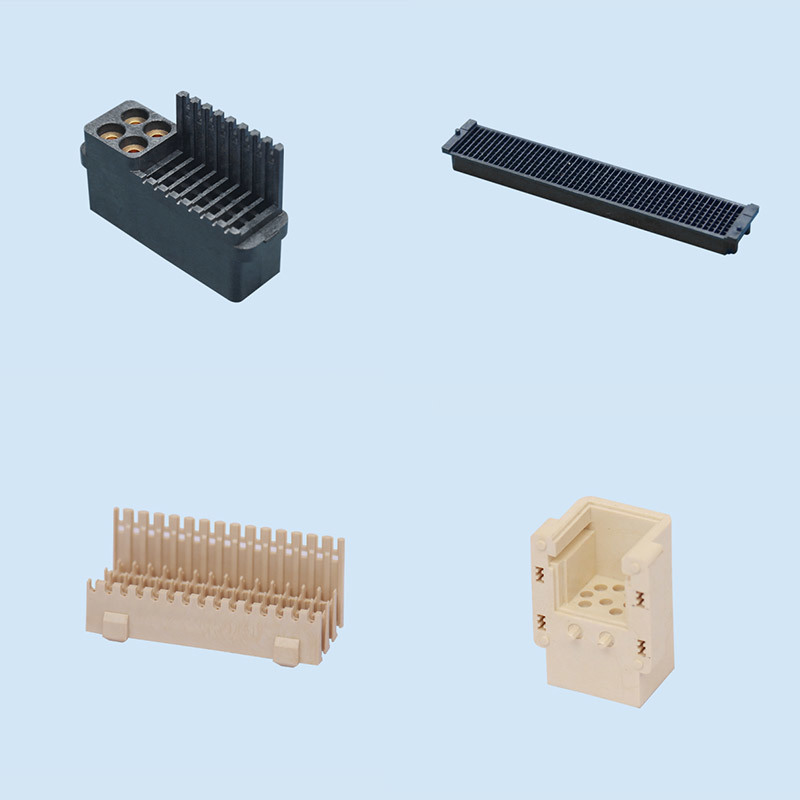

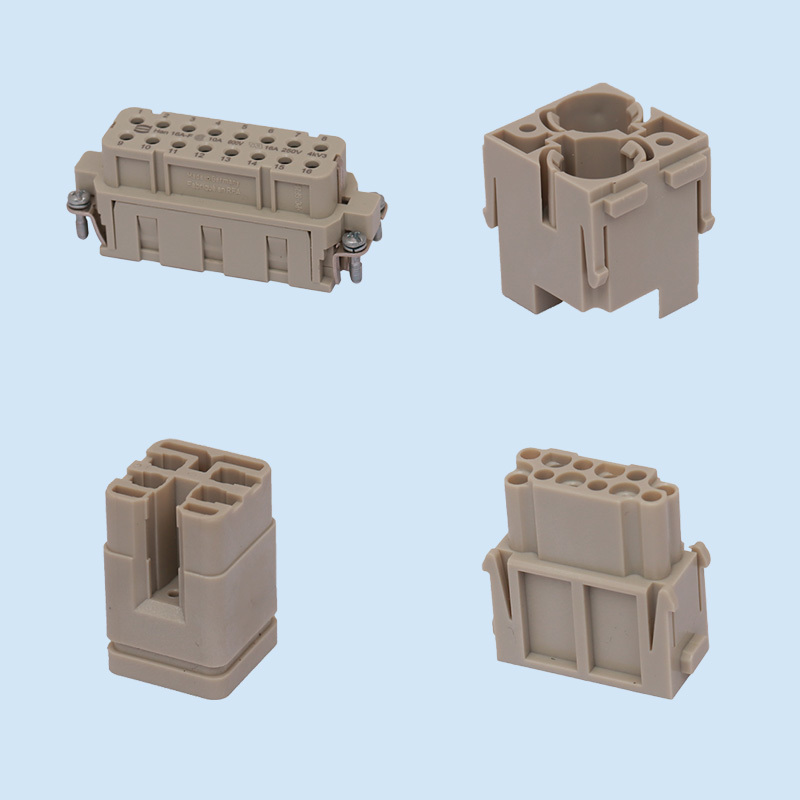

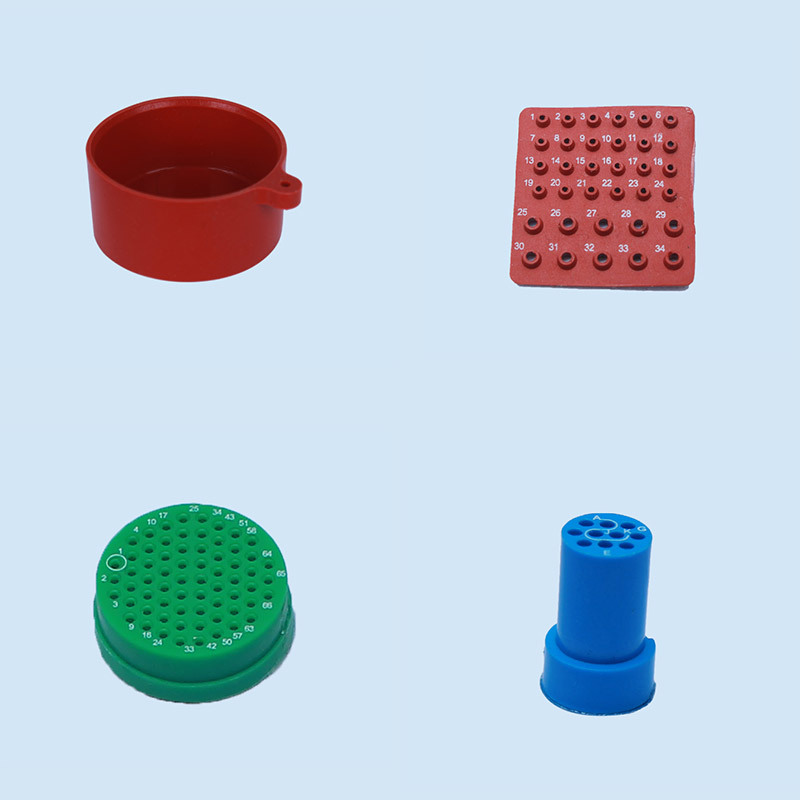

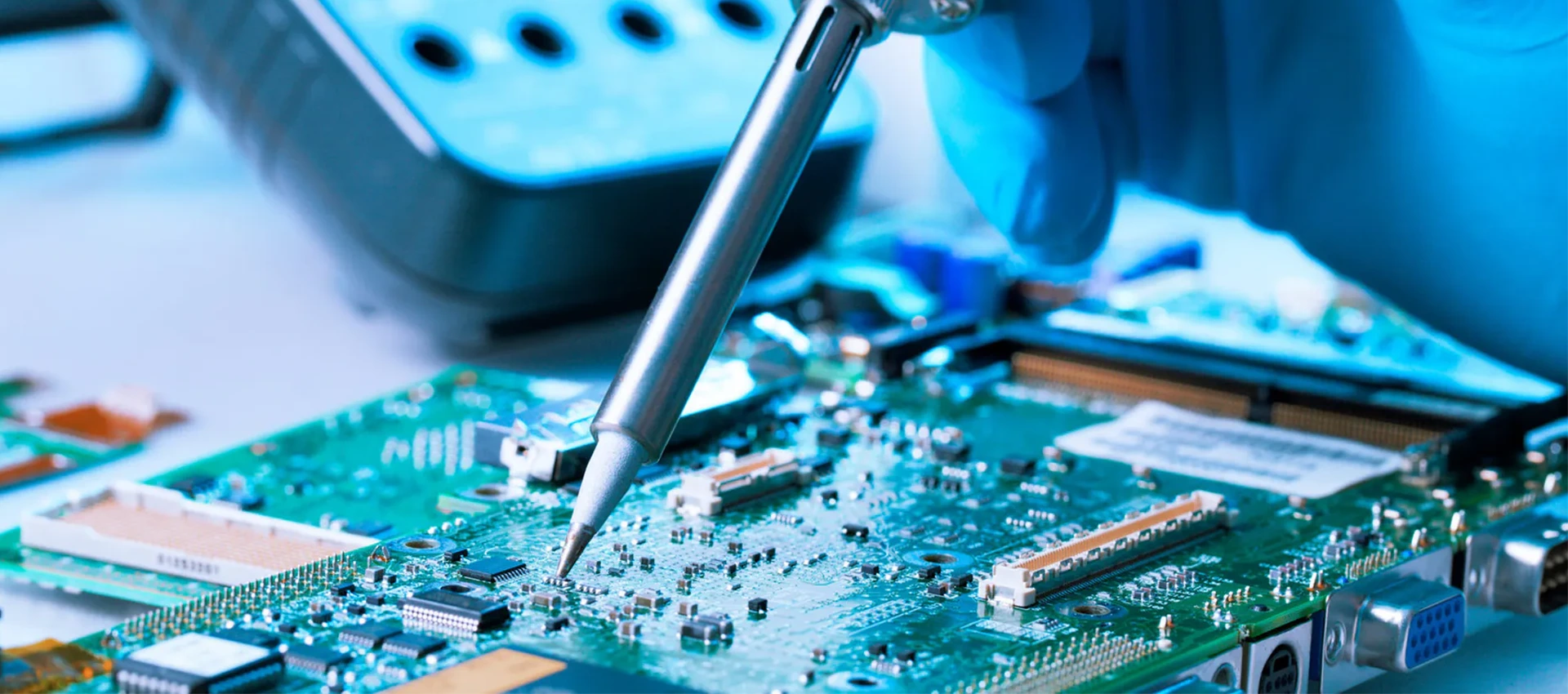

Precision injection molding, plastic parts manufacturing. Injection molding raw materials include PBT, PET, PA66/PA6, PP, PE, PC, ABS, PPO, TPU, TPV and other common engineering plastics, as well as PPA, PA1010, LCP, PPS, PI, PEI, PES, PEEK and other special engineering plastics. Plastic raw materials cover silicone rubber, fluorine rubber, fluorine silicone rubber, fluorine butyl rubber and so on.

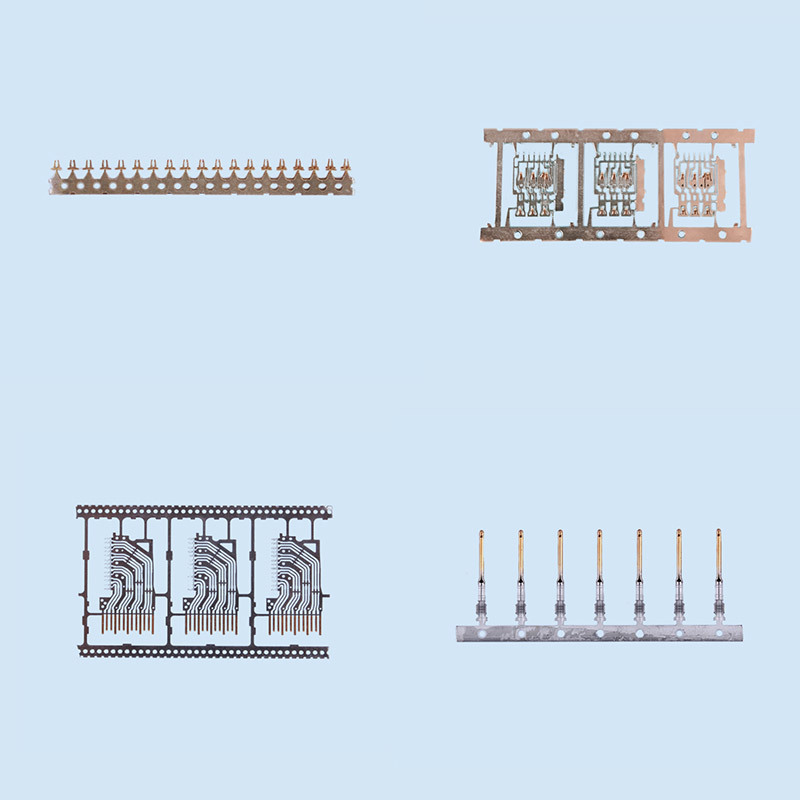

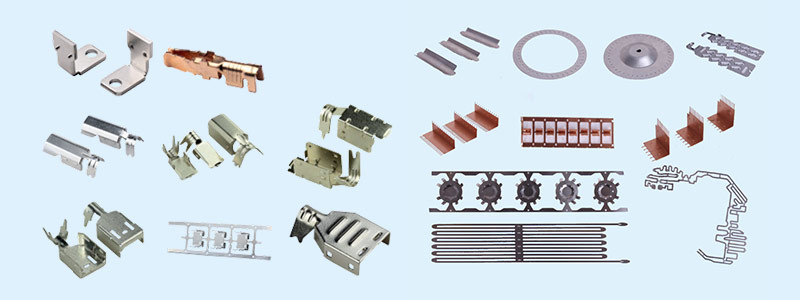

Manufacturing of precision hardware terminals and other stamping parts. Raw materials cover all kinds of copper, aluminum, iron, stainless steel, etc.

All kinds of plastic, metal parts machining and precision mold parts custom processing.

Product

Business Scope

About Us

Luoyang Linuo Mould Co.,ltd

Luoyang Linuo Mould Co.,ltd was established in 2005 with a registered capital of 30 million yuan. its production base is located in shuangxiang ring road, luoxin development zone, Luoyang city, Henan province. it covers an area of 30 mu, has a construction area of 20000 square meters, has an annual output value of over 0.15 billion.

The company is a national "specialized and special new" small giant enterprise, and a backbone enterprise of Luoyang electronic components industry cluster and aerospace industry cluster.

Company established in 2005

Construction area of nearly 20000 square meters

Registered capital RMB 3000 million

Why choose us?

R & D and manufacture all kinds of high-precision injection molding, stamping, plastic pressure mold; high-precision injection molding parts, stamping parts, plastic parts; precision mold accessories. The products can meet the characteristics of high precision, high durability, high temperature resistance, corrosion resistance, flame retardant, anti-static, electromagnetic shielding, anti-radiation, anti-instantaneous high current and high voltage, and compliance with various environmental protection standards.

Equipment & Capacity

The company has more than 300 sets of various high precision equipments. With an annual output of 2,000 sets of high-precision molds, more than 1 million pieces of various types of mold parts, and 400 million pieces of various types of plastic and metal parts.

Quality Control

The company has realized the comprehensive introduction of the three major quality systems of ISO9001, IATF16949 and GJB9001C, which can fully guarantee the quality of products.

R & D

The company has a strong design and development capabilities, is the Ministry of Industry and Information Technology provincial advanced mold industrial design center, with more than 30 design and development personnel, 57 patents.

Blog

The Buzz on Stamping Parts: What You Need to Know!

2025-05-05

Innovations and Trends in Stamping Parts: What You Need to Know

2025-04-30

Unveiling the Magic of Plastic Press Molds: A Revolution in Manufacturing

2025-04-25

The Evolution of Plastic Press Molds: Trends and Innovations

2025-04-20

Partners