Stamping Hardware

Classification:

Introduction

The company has more than 300 sets of high-precision wire cut, high-speed machining center, fine carving, high-precision mirror electric spark machine, CNC lathe, surface grinder, tool grinder, centerless grinder, precision milling machine, high-speed precision injection machine, high-speed punch, plastic press and other equipment. With the ability to produce 2000 sets of high-precision molds, more than 100 million mold parts and 0.4 billion plastic and metal parts annually, it is a large-scale research and development and manufacturing base for molds, plastic and metal parts in Henan and its surrounding areas, and has been fully imported into ERP and MES systems.

R & D and manufacture all kinds of high-precision injection molding, stamping, plastic pressure mold; high-precision injection molding parts, stamping parts, plastic parts; precision mold accessories. Products are widely used in new energy vehicles, military and civilian photoelectric connectors, aerospace, navigation, weapons and equipment, communications, rail transit, intelligent equipment manufacturing, electronic appliances and other industries. The products can meet the characteristics of high precision, high durability, high temperature resistance, corrosion resistance, flame retardant, anti-static, electromagnetic shielding, anti-radiation, anti-instantaneous high current and high voltage, and compliance with various environmental protection standards.

Development of precision injection molding, plastic pressing and stamping dies. In defense, new energy, automotive, communications, photovoltaic, high-speed, civil and industrial connectors and other fields have deep mold design, manufacturing experience.

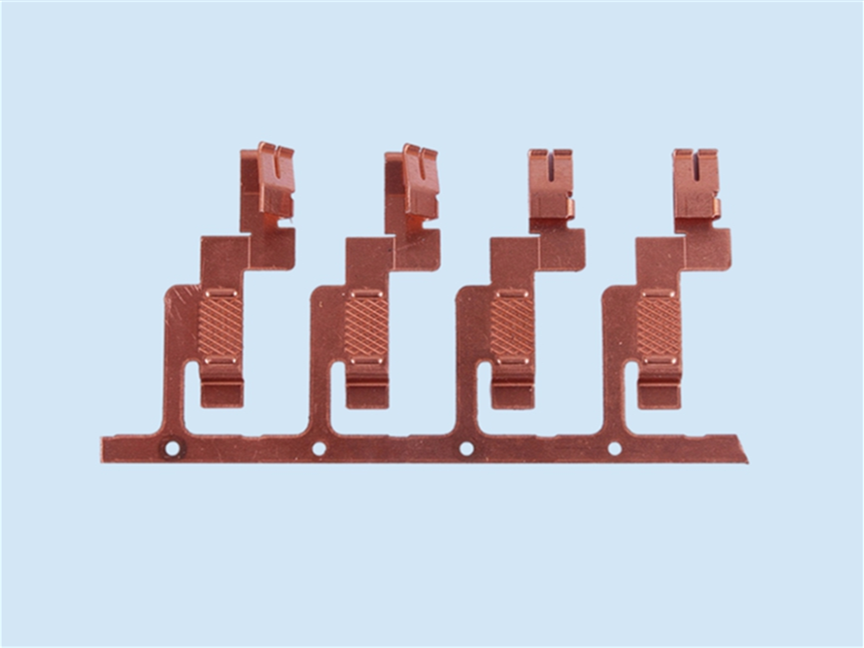

Manufacturing of precision hardware terminals and other stamping parts. Raw materials cover all kinds of copper, aluminum, iron, stainless steel, etc.

Precision injection molding, plastic parts manufacturing. Injection molding raw materials include PBT, PET, PA66/PA6, PP, PE, PC, ABS, PPO, TPU, TPV and other common engineering plastics, as well as PPA, PA1010, LCP, PPS, PI, PEI, PES, PEEK and other special engineering plastics. Plastic raw materials cover silicone rubber, fluorine rubber, fluorine silicone rubber, fluorine butadiene rubber, nitrile rubber, chloroprene rubber, etc.

All kinds of plastic, metal parts machining and precision mold parts custom processing.

Key words:

Stamping Hardware

Related Products

Inquiry